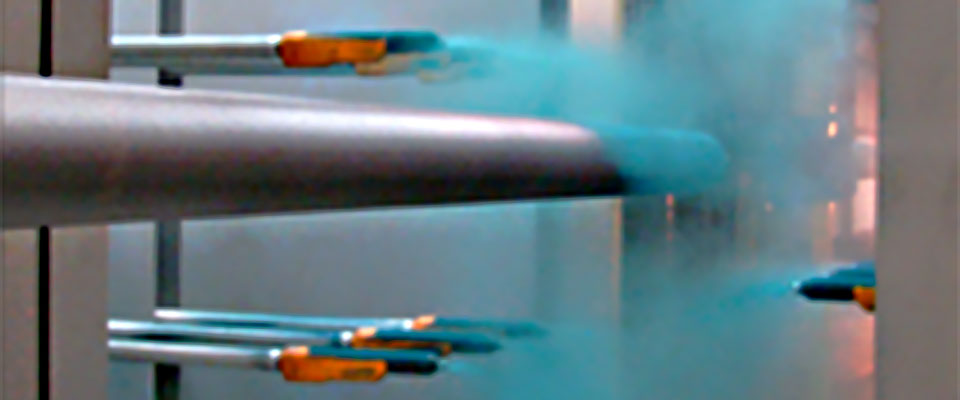

You may already know that every United Lighting Standards light pole automatically comes with a three-year warranty. But we also offer the option for extended five- and ten-year warranties that include more comprehensive finishing processes. The five-year warranty includes a Palgard Epoxy Coating; the ten-year warranty includes that coating plus galvanization. Since aluminum and fiberglass poles can’t be galvanized, ten-year warranties are only available for steel poles.

While the finishing process is nearly identical for both the five- and ten-year warranty options, the differences lie in the preliminary stages.

Preliminary Stage: Five-Year Warranty

Cleaning – First, we inspect your light pole for visible deposits — such as oil or grease — and remove surface imperfections like sharp edges, weld spatters, and burning slags.

Then, we clean the pole with our four-wheel shot blaster system to remove any rust, mill scale, oxides, and other particles. We remove any imperfections that remain on the pole with compressed dry air.

Cleaning Stage: Ten-Year Warranty

Enhanced Cleaning – To prepare your steel pole for galvanization, we’ll remove surface imperfections like weld spatters, sharp fins and edges, and burning slag. Then we run the pole through a five-step surface preparation to remove any other contaminants that may be present:

- 1. Caustic Cleaning: We immerse the pole in an acid de-greasing bath. It’s a caustic solution that removes dirt, oil, and grease from the surface.

- 2. Rinsing: We rinse the pole to remove the caustic solution.

- 3. Pickling: We immerse the pole in an acid tank to remove oxides and mill scale.

- 4. Rinsing: We rinse off the acid.

- 5. Flux Solution: We immerse the steel in a solution that creates a protective coating to prevent it from oxidizing before the galvanization process.

Galvanizing – At United Lighting Standards, we use the hot-dip form of galvanization. We’ll dip the pole in a molten bath of zinc at a temperature of 860 degrees. When exposed to oxygen and carbon dioxide, the pure zinc forms zinc oxide and zinc carbonate, which is dull grey in appearance. Once the pole is completely galvanized, it’s preheated and mechanically etched.

Final Stage: Both Five- and Ten-Year Warranties

Powder Coat Application – Applying 6 mils of powder coating provides excellent corrosion protection. Note that galvanized poles don’t require a powder-coat finish, but this is an option. Click here to learn more about the benefits of powder coats.

Curing – Once the powder is applied, we’ll cure (or “crosslink”) the pole by baking it in a 450-degree oven to chemically bond the powder with the metal.

Phosphate Rinse (Steel Poles Only) – After cleaning and/or galvanization, we’ll coat your steel light pole with iron phosphate, which creates an iron oxide base. That’s followed by a flat or amorphous metal phosphate topcoat. Those processes improve bonding, minimize oxidation if the coating is scratched, and improve corrosion resistance.

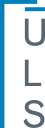

Blue Wrap – Once the pole is cooled, we wrap it in our signature blue packaging. It’s a multi-layered, UV- and tear-resistant vinyl bubble wrap that protects the pole until it reaches your job site.

Ready to chat warranties? Talk with Joe. Want to learn more about each of our warranties? Click here.