The questions below are those we often receive from our downstream partners regarding what products we offer, how to correctly place an order with us, or the status of an order in process.

Hopefully this page helps you with any questions you might have, but don’t hesitate to contact us directly if not.

When is it necessary to add a vibration dampener to a pole?We typically recommend a

vibration dampener when installing poles that are 25’ or taller; in areas that are known to experience constant, low-velocity winds; or when wind-induced vibrations have been proven to effect other nearby structures.

When dealing with steel poles, in most cases, we can modify the base plate to fit any existing bolt circle. When dealing with aluminum bases, there are limits to what bolt patterns we can match. In any case,

contact Project Management to verify if the base plate can be modified and the cost of the modification.

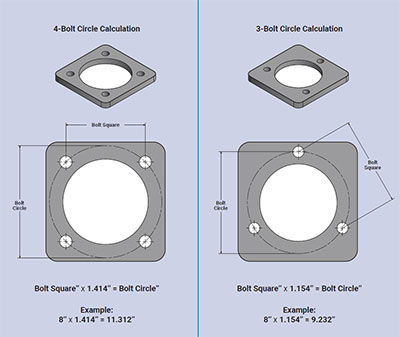

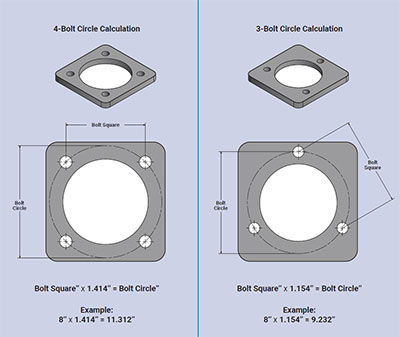

When measuring a 4-bolt pattern, center bolt to center bolt at a diagonal will give you the bolt circle. If that measurement is not possible to do, you can measure from center of bolt to center of bolt side to side. This number will give you the bolt square. You then multiply that by 1.414, and this will give you the bolt circle.

Click here for an illustration of this calculation.

When measuring a 3-bolt pattern, measure from bolt to bolt and multiply that by 1.154. Click here for an illustration of this calculation.

Contact us with any questions you might have about these calculations.

When trying to figure what size pole is needed, we need to know the number of fixtures, brackets, and any other accessories that will be going on the pole and where these items will be located on the pole (in relation to the hand hole). Most importantly, we need to know the EPA (effective projected area) value of each of those items if at all possible. Refer to our

Mounting Orientation Guide for information on how to denote proper placement of fixtures, brackets, accessories, and options. If you are unsure about how to provide any of this information,

get in touch with our Project Management Team, who is happy to help.

Anchor based poles come with a metal base plate that holds 3, 4, and 6 (most typical) anchor bolts that are cemented into the ground. Embedded poles are directly buried into the ground; thus, they don’t have a base plate nor do they require anchor bolts. With embedded poles, a longer pole shaft is required to compensate for the amount of pole that needs to be buried in the ground. Typically, whatever fixture mounting height you need, take 10% of that plus 2’ and that’s how much of the pole needs to be buried. For example, a fixture mounting height of 20’ requires that 4′ be buried — equaling the need for a 24’ pole.

What are your standard colors/finishes?You can

view our standard colors on our website. Custom colors are generally readily available for an additional color set-up charge. For any non-standard color finish, contact our Project Management Team for pricing.

Our products get to market solely through our lighting manufacturer sales representatives across the country.

Find a Sales Rep on our website by selecting a state in the drop-down menu. Our sales reps will be able to provide you with pricing and lead times on our products as well as help create the ideal lighting layout for your area site lighting needs.

Contact Project Management with a detailed description or sketch of what is needed and we will advise you on a proposal. We manufacture a wide variety of custom poles and brackets.

For questions about orders that have already been submitted, contact project management.

Do you make anchor bolt goof plate?Yes, we manufacture our

Two-Tier Adapter Plate, otherwise known as a “goof plate.” When anchor bolts are set incorrectly in the field, the Two-Tier Adapter Plate greatly reduces the labor required to correct the situation by fabricating the bottom base plate to accept the positioning of the incorrectly set anchor bolts and the top base plates provides the correct bolt circle required by the lighting standard. Each Two-Tier Adapter Plate is customized to fit the existing bolt circle as well as the required bolt circle. We then provide a custom steel base cover designed to aesthetically hide the fix and work with the other base covers on the job site.

Pole pricing includes an ABS base cover (steel poles), nut covers (aluminum poles), anchor bolts, hand hole with cover, and either drilling the pole top for up to 4 fixtures or a standard size tenon. For our current Sales Reps,

log into PoleVaultTM to view pricing information.

We recommend contacting a qualified professional engineer licensed for and familiar with the local soil conditions and other structural safety factors to design the concrete foundation.

What finish can I order on my pole?We offer a powder coat, galvanized, or powder coat over galvanized finish for all of our steel poles. Aluminum poles come in powder coat, or anodized finish.

Click here for more information about our finishing process.

To help expedite the release of orders to our production team, it is important that we receive all of the following information for each order:

- Complete ship-to address

- Job-site contact name, phone number, and email address

- ULS quote number

- Distributor purchase order number

- Any deviations from standard mounting configurations

- Signed-off specifications drawings

- Complete order number, along with fixture information (click here for information on how to create a ULS order number)

In order for an order to be released, we must have completed

freight authorization forms on file.

Contact Project Management to find out if this is what is preventing the release of your order.

Most orders are shipped using brokered independent flatbed carriers to ensure our poles arrive damage free. Small parts orders or anchor bolts of poles are shipped via UPS.

Every effort will be made to accommodate a customer request for a specific carrier if the customer accepts to pay associated freight costs. In these cases, the freight carrier and account number should be noted on the purchase order.

Click here for more Shipping & Handling information.