What’s Happening in the Steel Market?

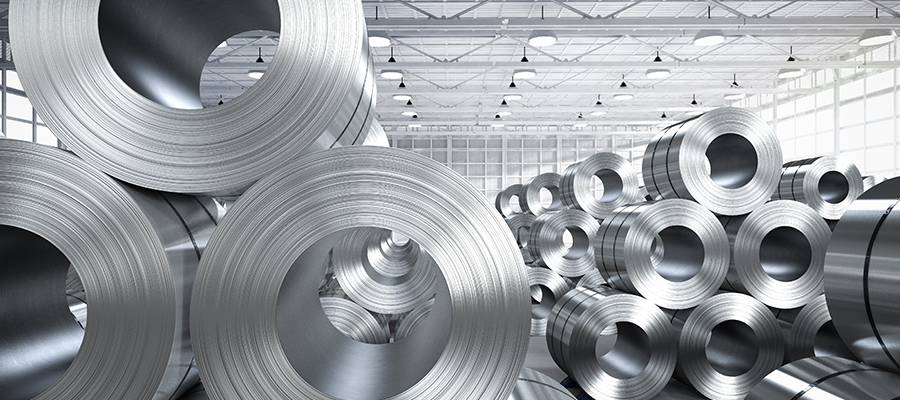

When COVID-19 caused America to shut down in early 2020, the demand for steel products decreased. Then, from March to August of 2020, demand remained relatively stable.

As local markets across the U.S. have begun to reopen and both commercial and public construction has picked up, we are seeing unprecedented spikes in the demand for many raw materials, including steel. As a result, steel mills are struggling to meet the demand, skyrocketing raw steel costs and limiting availability.

During previous metal shortages, many manufacturers turned to purchasing materials from other countries, but, due to tariff increases, challenges at the port and a worldwide material shortage, this is currently not a reliable option.

How Demand Impacts Pricing

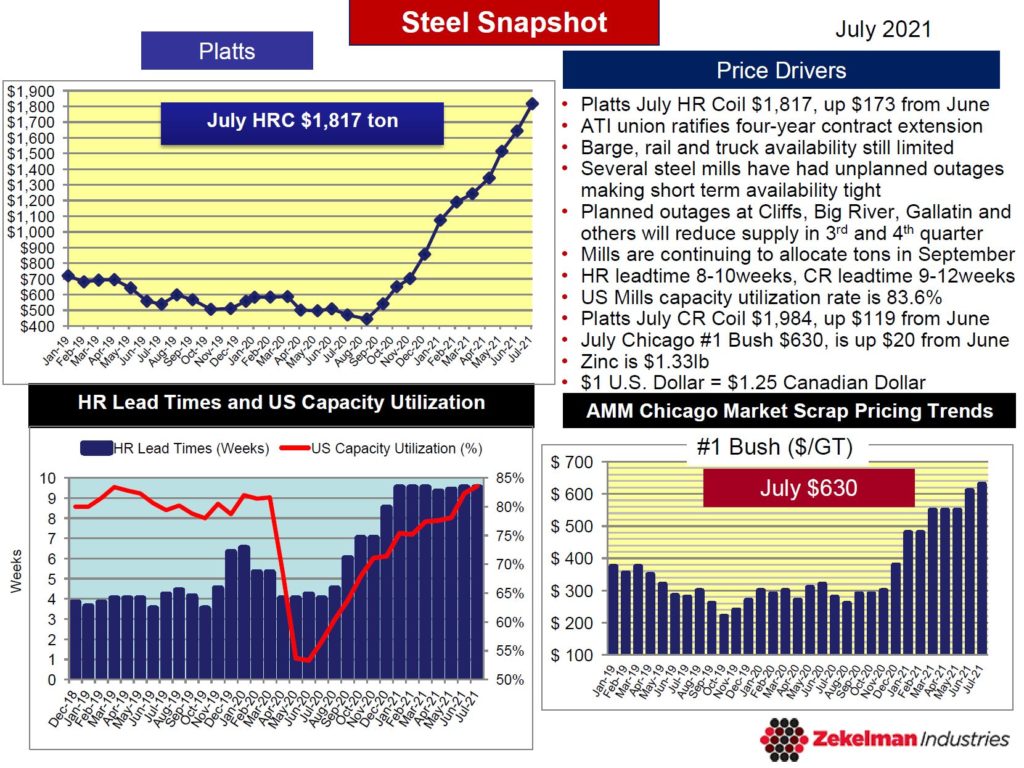

To put some historical perspective around this, hot-rolled steel has moved from a low of $440/ton in mid-August of last year to $1,817/ton as of July 14, 2021. The previous high of $1,070/ton was recorded in July 2008.

As demand increased at the end of summer 2020, we started seeing significant jumps in steel prices. Between August and October, the price increased 7.5%. Since August, prices have skyrocketed:

- December 2020: The price jumped 20%.

- January 2021: Steel price increased 37%.

- February through March 2021: The price was up another 75%.

In addition to pricing levels, lead times for spot orders from the mills are another indicator of steel demand. Lead times for hot-rolled orders now exceed nine weeks, while cold-rolled orders are extending into 12 weeks, both of which are triple the normal wait time.

Unfortunately, market data suggests that this situation won’t be course correcting any time soon. Here’s a snapshot from one of our steel manufacturing partners, Zekelman Industries.

How That Impacts Light Poles

Since we purchase our metal directly from domestic steel mills, we’re challenged in the ability to source enough material to meet the current demand for our light pole products within the lead times our sales partners and customers have come to expect. Many mills are restricting customers to previous purchase amounts. And most aren’t currently able to take on new customers.

In response to the current environment, we, like most other manufacturers, have been forced to raise prices. Luckily, we’ve built strong relationships with our critical supplying partners, so we’re working to manage expectations around future cost and lead time changes to the absolute best of our ability.

What Can You Do?

Communication is critical right now. Remember to prepare your customers for price fluctuations, longer lead times and limited availability.

And if you have an upcoming project that requires steel light poles, get your purchase orders in as soon as you can and we’ll do our best to make sure you get your poles on time.

As we continue monitoring the steel market, we’ll keep you informed of any changes we experience.