The poles will be delivered with the anchor bolts and template (if not pre-shipped) and a box of hardware. The box of hardware must be inspected at the time of delivery.

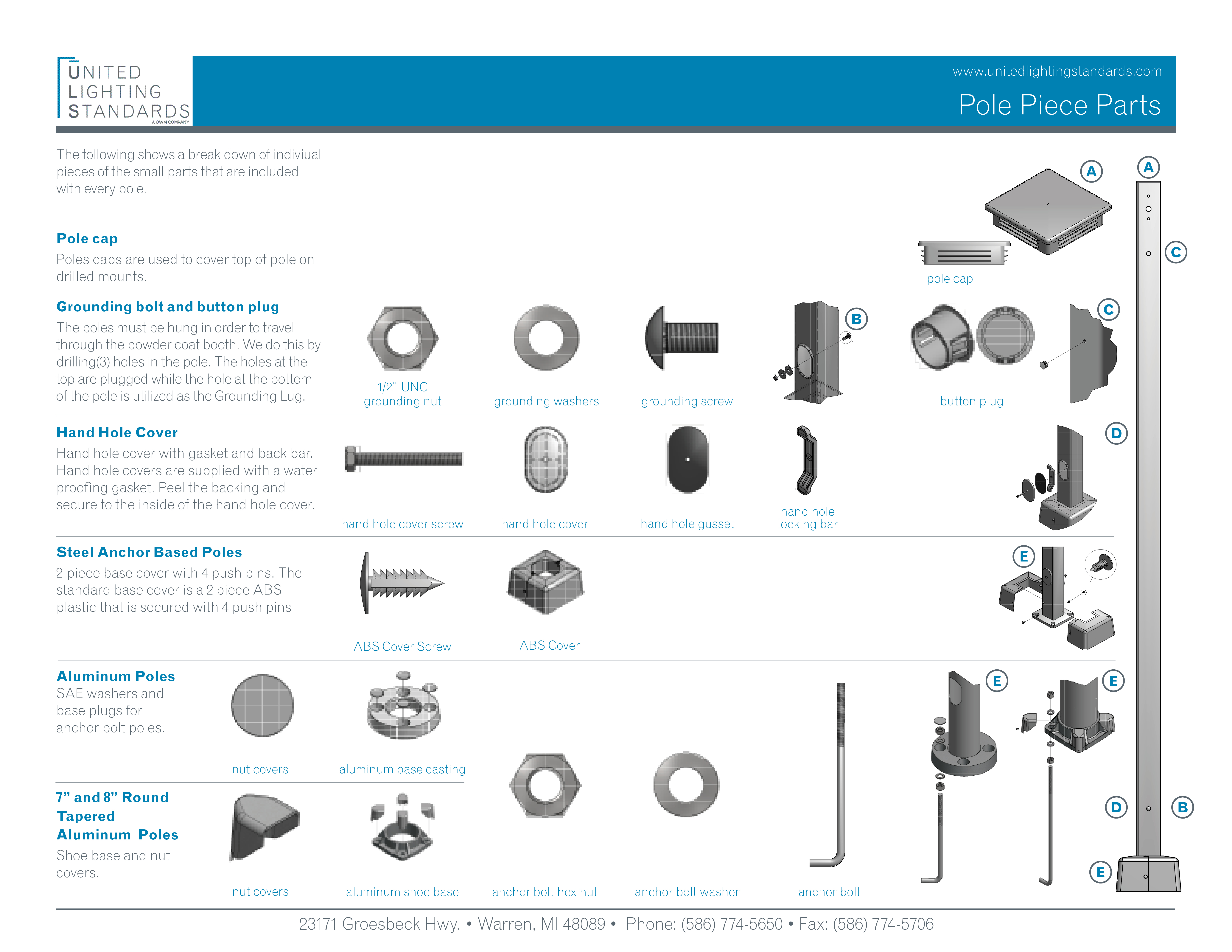

During production, our poles must be hung in order to travel through the powder-coat booth. To accommodate this, we drill two holes in the pole, one at the top and one at the bottom (opposite the hand hole). The hole at the top is plugged while the hold at the bottom of the pole is utilized as the grounding lug.

United Lighting Standards has been committed to designing, fabricating, finishing, and packaging high-quality steel and aluminum poles since 1971. We adhere to standards set forth by AASHTO, ASTM International, and NEMA. All of our products are built using fabricating and welding procedures outlined in the American Welding Society (AWS) manual for steel and aluminum to eliminate welding defects and ensure structural integrity.

Read more about ULS